Modular Acoustic Enclosures for VRF/VRV single systems or system combinationsThanks to the modular design, existing system groups can also be easily retrofitted with a sound bonnet that is designed for the corresponding system dimensions and air volume. |

|

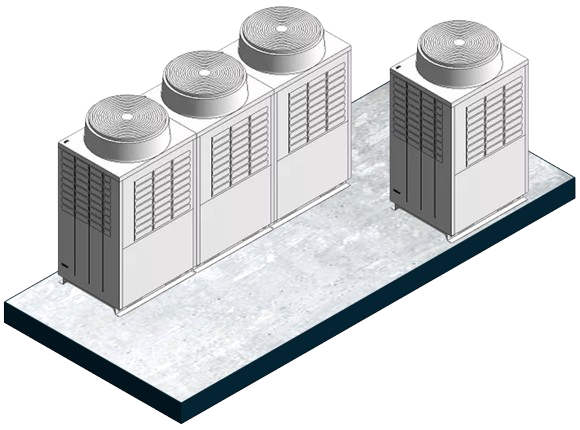

/VRV are on the rise and can be used in all buildings that need to be cooled and/or heated in an energy-efficient manner. In office buildings, hotels, boutiques, shops, surgeries, laboratories and residential buildings, VRV/VRV systems are increasingly being used for centralised air conditioning.

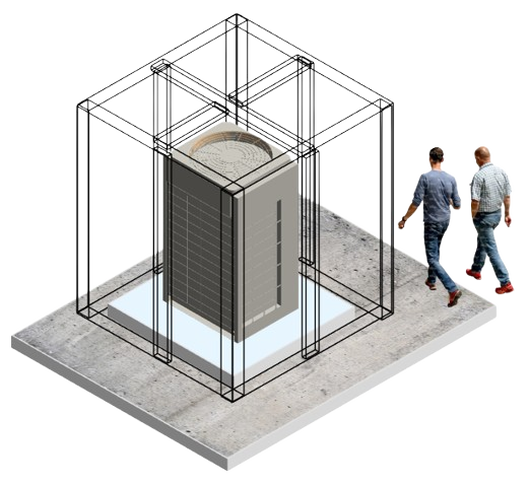

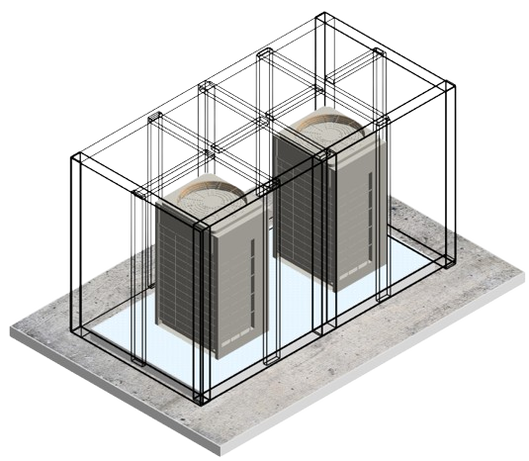

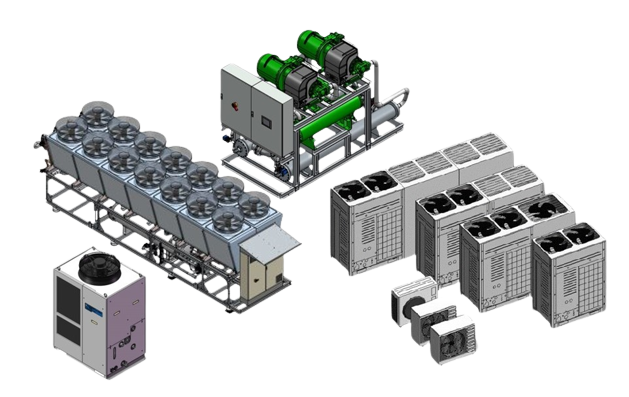

Due to their widespread use, VRF/VRV systems are being installed more and more in areas with dense construction, where they meet the quiet requirements of residents. Our modular acoustic enclosures are used here for the sound insulation of individual systems or groups of systems. With a noise reduction of up to 25 dB(A), VRF/VRV systems can also be installed in close proximity to the neighbourhood. Thanks to the modular design, existing system groups can also be easily retrofitted with a sound enclosure that is designed for the corresponding system mass and air volume. Of course, the acoustic enclosures can also be installed in new systems. The acoustic enclosures can be supplied either disassembled or assembled. VRF/VRV are on the rise and can basically be used in all buildings that are to be cooled and/or heated in an energy-efficient manner. |

We supply acoustic enclosures for VRF/VRV systems from the following manufacturers:

VRV DAIKIN VRF MITSUBISHI / SAMSUNG / PANASONIC / HITACHI / FUJITSU / TOSHIBA / LG / CARRIER / YORK / CLIVET / JOHNSON CONTOLS / SWEGON etc.. |

|

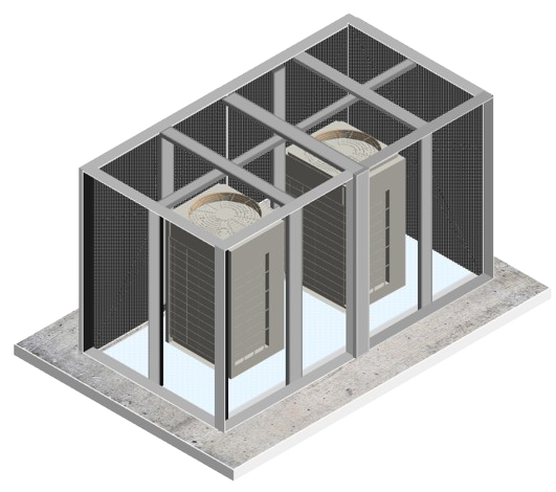

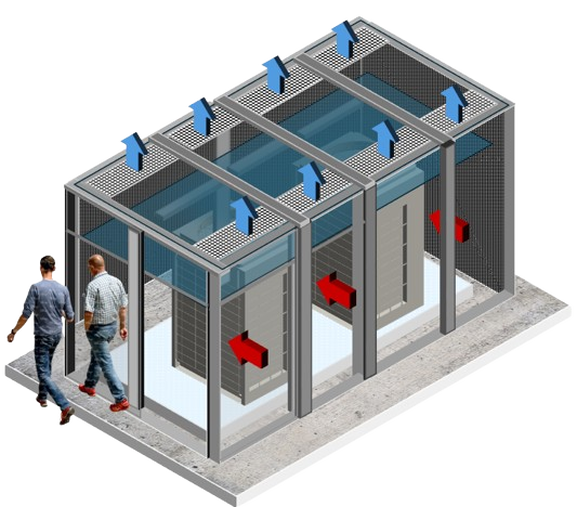

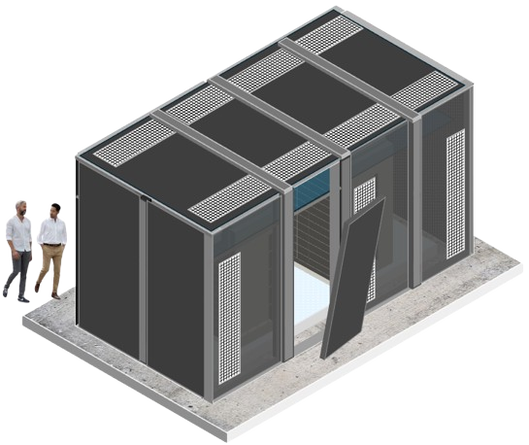

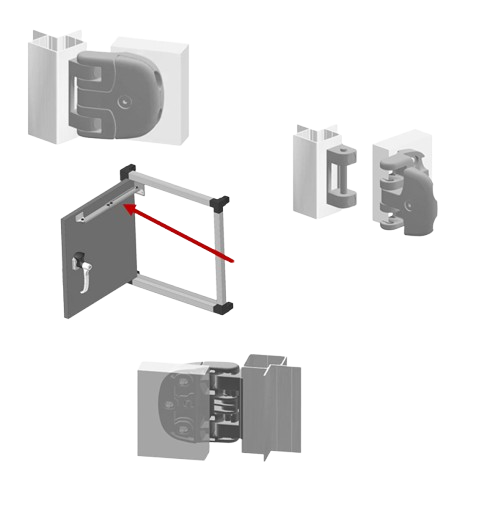

Our VRF/VRV acoustic enclosures are based on a self-supporting frame construction made of aluminium profiles that can be assembled very quickly and without special tools and can also be adapted to a wide variety of system sizes and system combinations.

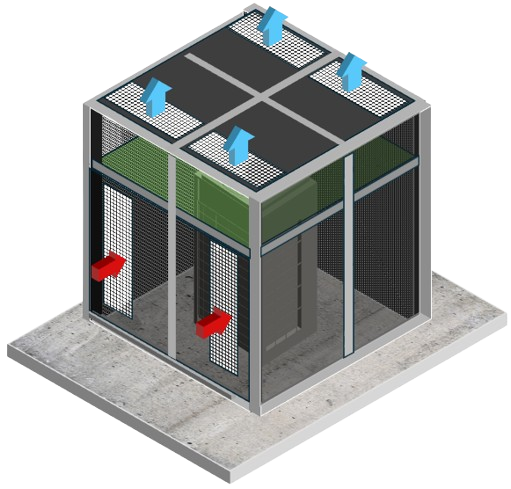

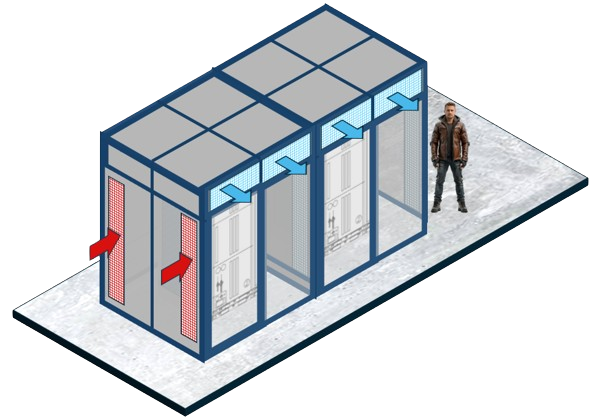

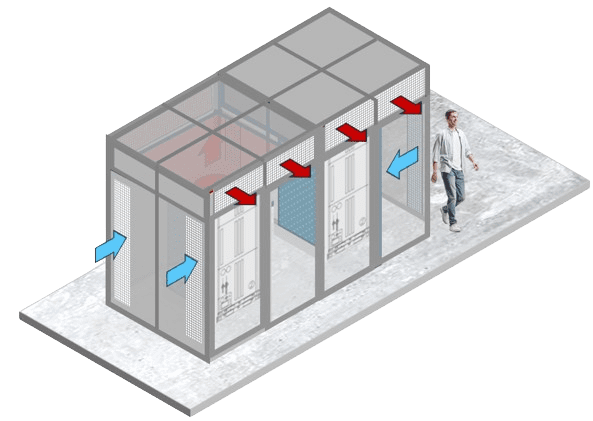

In addition, the acoustic enclosures can be installed on construction sites without any problems, even in confined spaces - i.e. passageways. The service doors around the system can be opened in seconds using quick-release fasteners. This means that the systems remain accessible for service and maintenance work without restriction and no additional maintenance clearance needs to be taken into account when planning the systems. The service doors are made of 1.5 mm thick aluminium sheet, which is fitted on the inside with an innovative 40 mm thick insulation made of closed-cell, semi-rigid and sound-absorbing polyethylene foam panels. Air Routing Single VRV/VRF EnclosureSound reduction of up to 21 dB(A) through sound insulation, sound absorption, prevention of sound reflection |

Base Frame VRF/VRV Single UnitBase Frame VRF / VRV multiple systems and system combinationsVRV/VRV acoustic enclosures with service doors around the systems (tilt dimension 6 cm)Example calculation of free areas, air volume and air velocityTo calculate the free air area at an air volume of 28,000 m³/h and an air velocity of 4 m/s, we must first convert the air volume into the same unit of time as the air velocity and then apply the formula. Calculation

The free air area is therefore 1.9444 m². This calculation shows that for an air volume of 28,000 m³/h at an air velocity of 4 m/s, a free air area of around 1.94 square metres is required to supply the system with sufficient air. |

Our VRF and VRV acoustic enclosures can be adapted to different system sizes and installation situations |

Thanks to the modular design, individual modules up to 6 metres in length and width and a height of around 3.5 metres can be easily realised. Larger systems can also be built by combining individual modules.

The sound enclosure height takes into account the fact that most VRF/VRV systems are mounted on subframes such as ‘Big Foot Support Frames’ or, for example, the Daikin subframes with oil and condensate water tray.

Here too, however, the acoustic bonnet is always designed to optimise system performance despite the enclosure.

1 ) Difficult installation situations

2 ) Special requirements for the air flow and air routing.

3 ) Size, air routing, bonnets for more than one system.

4 ) Sound enclosures for cascades

The sound enclosure height takes into account the fact that most VRF/VRV systems are mounted on subframes such as ‘Big Foot Support Frames’ or, for example, the Daikin subframes with oil and condensate water tray.

Here too, however, the acoustic bonnet is always designed to optimise system performance despite the enclosure.

1 ) Difficult installation situations

2 ) Special requirements for the air flow and air routing.

3 ) Size, air routing, bonnets for more than one system.

4 ) Sound enclosures for cascades

|

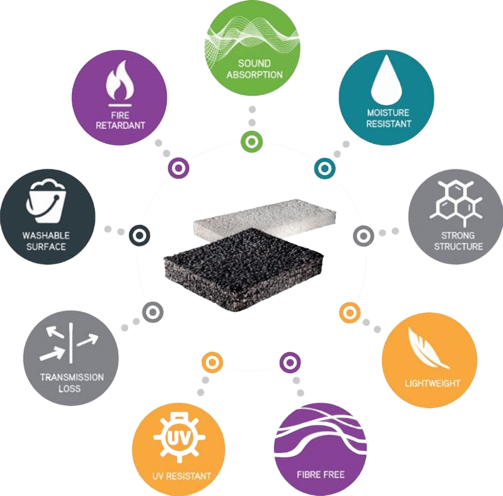

All service doors are fitted with internal sound insulation. We use ‘StratocallWhisper FR’ with a thickness of 40 mm due to its excellent sound insulation properties over a wide frequency band.

Stratocell®Whisper® is a product range with closed-cell, semi-rigid and sound-absorbing polyethylene foam panels. Thanks to its sound-absorbing properties, this foam is one of the most innovative materials for sound control in industry and construction. Thanks to the numerous certifications, the panels can be used in the following areas: Construction, industry, rail vehicles, the automotive industry, the electronics sector, shipping, canalisation and air conditioning. As the material is water-resistant, it can also be used in damp environments. The closed-cell structure, the high degree of sound insulation, the resistance to water and moisture, the self-supporting structure and the specific certifications give this innovative product unique features that pay off in full when used in our acoustic enclosures. |

VRV/VRF Enclosure with Sensors TechnologyIn the limited atmospheric space of our acoustic bonnets, NDIR refrigerant sensors detect even the smallest leaks at the refrigerant connections and in the refrigerant circuit with a resolution of up to 1000 to 2000 ppm in the outdoor units. If a quantity of refrigerant is detected, an alarm is triggered. In the case of flammable refrigerants, the sensors are also combined with a storm ventilation system.

The ‘NDIR sensors’ used are maintenance-free, do not require annual calibration and are not cross-sensitive to flammable or toxic gases. Temperature and humidity fluctuations are also not a problem. The sensors are also protected from splash water by a special coating. For the detection of natural refrigerants, specific sensors orientated to the refrigerant are used. |