|

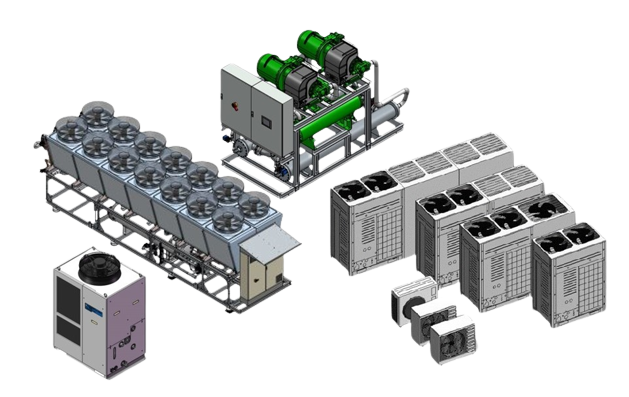

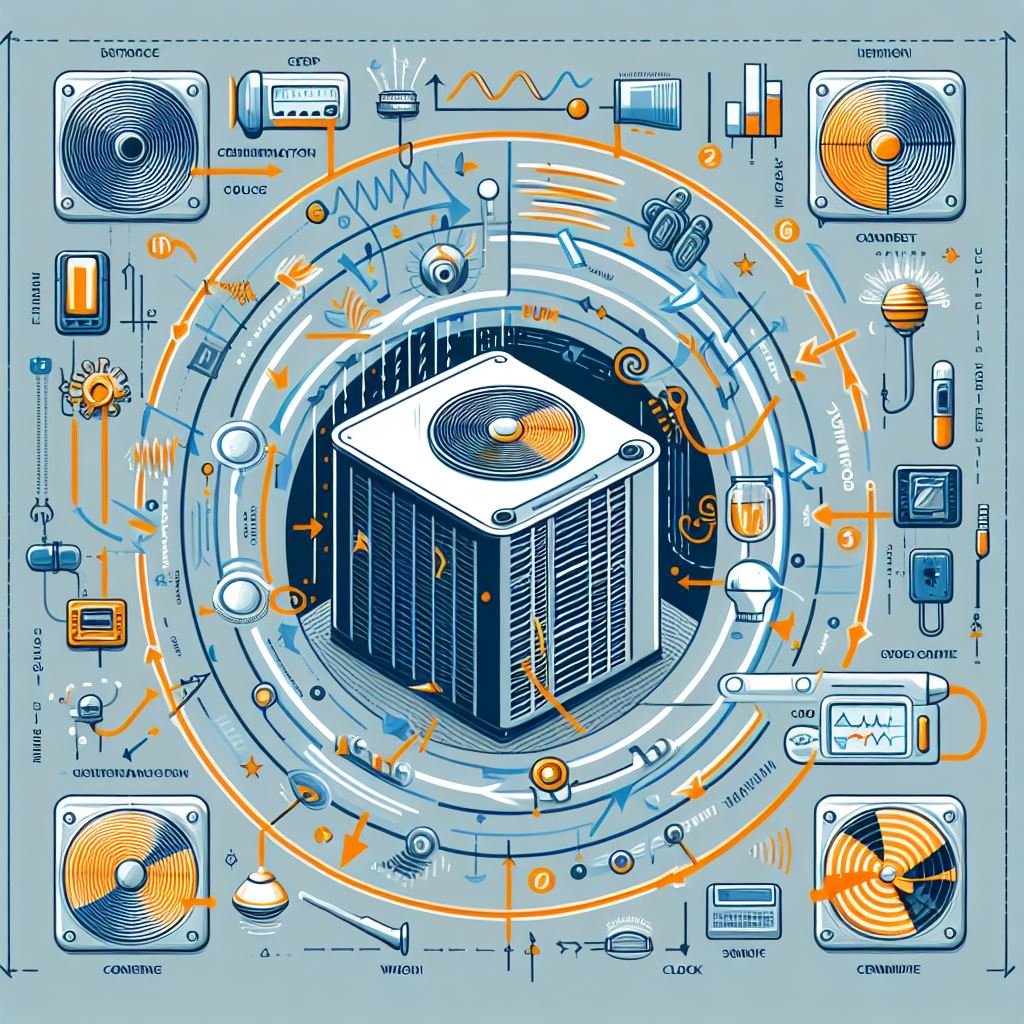

The acoustics of systems can be an important indicator of the condition and performance of HVAC systems and machines in general. By , anomalies can be detected and potential problems identified at an early stage.

This method is referred to as “Acoustic Predictive Maintenance” and is an example of predictive maintenance that will replace “preventive maintenance” concepts in HVAC systems. “Acoustic Predictive Maintenance” is a method based on the analysis of noise and vibrations. The continuously recorded machine noises are compared with the noise data from normal operation in order to derive statements about the operating status. Noise and vibration analysis is used to detect anomalies and identify potential problems at an early stage. The data is evaluated in real time and compared with the reference data. If deviations are detected, suitable measures can be taken to prevent or minimize damage. By evaluating acoustic data in combination with information from air pressure, refrigerant, humidity and temperature sensors, HVAC systems can be monitored virtually seamlessly in real time, reducing unplanned downtime, extending the service life of systems and cutting maintenance costs.

0 Comments

Leave a Reply. |

AuthorWe specialize in reducing noise emissions and increasing the performance of HVAC and industrial systems. Archives

January 2025

Categories |

We support you in solving noise problems - even at your premisesSilent Engineering

di Vicari Romolo Via Trento 22 IT-23875 OSNAGO (LC) www.forcotech.com [email protected] Phone: + 39 349 431 73 42 Contact Form VAT ID: 03833150133 Fiscal Code: VCRRML61E28Z133R Data Protection, Privacy, GDPR More Information ©Copyright (copyright notice) 2019/ 2020 / 2021 / 2022 / 2023 / 2024 - Silent Engineering - All contents of this website are subject to copyright. All content, in particular texts, images, logos, product names and graphics are protected by copyright. All rights, including reproduction, publication, editing and translation, require the express written authorisation of the website owner. This will only be granted after verification via PEC mail or registered letter. |

Our Brands around soundproofing |

RSS Feed

RSS Feed