|

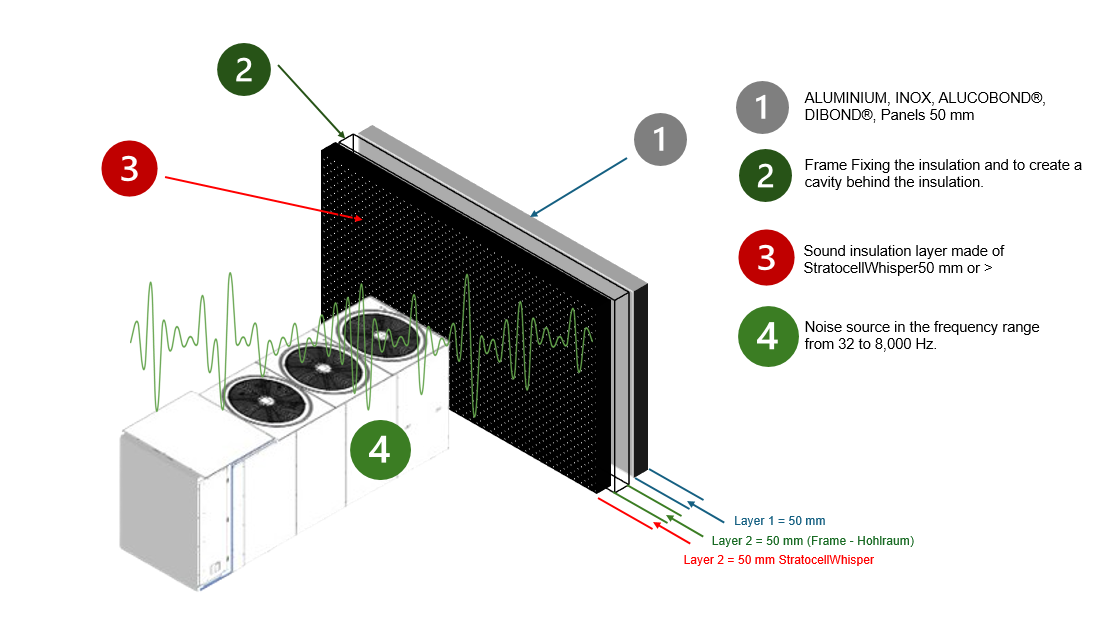

For us, the use of StratocellWhisper with a thickness of 50 mm or more in our sound insulation hoods and sound insulation walls for HVAC systems is undisputed. The material properties and the sound effect speak for themselves. For projects with very high sound insulation requirements, we also install a cavity between the insulation and the external panels.This results in several acoustic and technical advantages:

1) Significantly improved sound absorption: A cavity of 50 mm significantly increases sound absorption, as the distance between the wall and the insulating material acts like a resonator. This means that low-frequency sound waves are better absorbed, and the reflected sound energy is reduced. This is often used specifically in acoustics to increase the effectiveness of absorbers. 2) More efficient use of material properties: Stratocell Whisper is already designed as a sound-absorbing polyethylene foam that offers high sound insulation values thanks to its closed-cell structure. In combination with cavities, the effect of the material is further enhanced, as layers of air act as an additional damping layer. 3) Improved mechanical decoupling: The distance reduces the direct coupling between the wall and the insulating material, which further reduces the transmission of structure-borne sound and vibrations. On the side of the insulating material, we naturally do not cover it with perforated sheets or similar, so that the entire absorption surface of the insulating material is used. Conclusion: A cavity of 50 mm when installing Stratocell Whisper ensures significantly higher sound absorption, improves acoustic effectiveness and offers practical advantages in terms of installation and technical equipment. ity to improve sound absorption

0 Comments

Leave a Reply. |

AuthorWe specialize in reducing noise emissions and increasing the performance of HVAC and industrial systems. Archives

January 2025

Categories |

We support you in solving noise problems - even at your premisesSilent Engineering

di Vicari Romolo Via Trento 22 IT-23875 OSNAGO (LC) www.forcotech.com [email protected] Phone: + 39 349 431 73 42 Contact Form VAT ID: 03833150133 Fiscal Code: VCRRML61E28Z133R Data Protection, Privacy, GDPR More Information ©Copyright (copyright notice) 2019/ 2020 / 2021 / 2022 / 2023 / 2024 - Silent Engineering - All contents of this website are subject to copyright. All content, in particular texts, images, logos, product names and graphics are protected by copyright. All rights, including reproduction, publication, editing and translation, require the express written authorisation of the website owner. This will only be granted after verification via PEC mail or registered letter. |

Our Brands around soundproofing |

RSS Feed

RSS Feed