|

Noise protection measures are an important issue today when planning larger heat pumps, VRF/VRV and refrigeration systems. This is due to denser construction, greater sensitivity of the population to the environment and therefore also to noise, and stricter regulatory requirements.

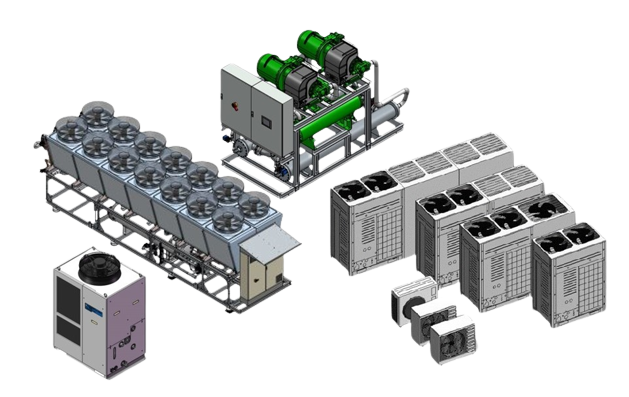

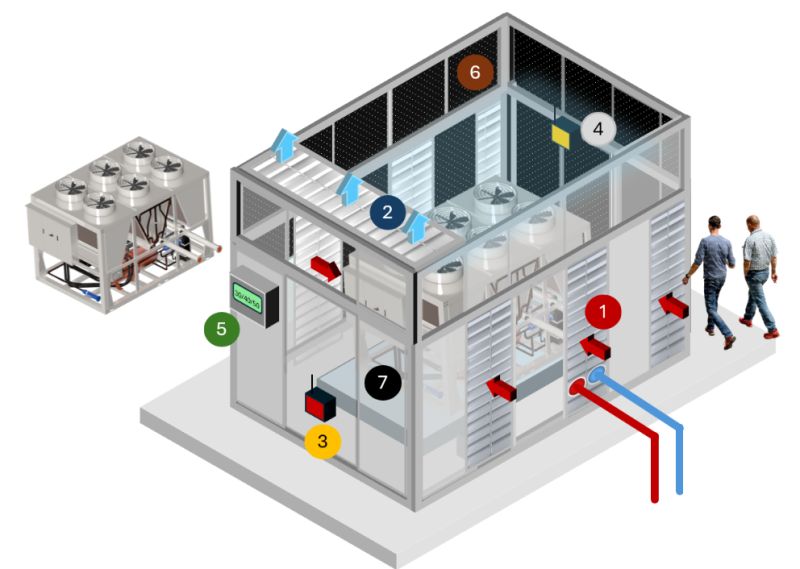

In many cases, this not only affects new systems, but also systems that are already in operation. This is where modern acoustic arbours come in, which not only aim to reduce noise emissions, but are also equipped with appropriate sensor technology to enable better control of the systems, monitoring of energy efficiency and early detection of anomalies in system operation. (1) /(2) Sensors for controlling the air inlet and outlet openings Control of the position of the air inlet and outlet louvres of the acoustic bonnet to optimise the air flow. The louvres can be set to 4 different positions via sensors to control the air volume flow: Closed louvres = example for cold start of a heat pump at low outside temperatures / 45° = normal operation of the system up to 50% air volume / 60° = normal operation of the system up to 80% air volume / 90° full load operation or ‘Free Cooling’ mode for refrigeration systems. (3) Refrigerant sensors Early detection of refrigerant losses and prevention of compressors running dry. Positioning of the sensors depending on the specific weight of the refrigerant. For systems with flammable refrigerant in combination with storm ventilation to prevent the accumulation of an ignitable quantity of refrigerant. (4) Air pressure sensors Air pressure sensors for measuring pressure losses and air velocity enable the systems to be optimised. The air velocity can also be optimised by combining this with controlling the position of the air inlet and outlet fins. (5) Sensor technology Measurement of temperature, humidity and sound Are a standard application in sensor technology. The air inlet temperature with the comparison of the temperature of the system's exhaust air is another way of identifying potential for optimising the systems. In future, the recording of acoustics during normal operation of the system with the ongoing adjustment of the acoustics during operation of the systems will be a possibility for the early detection of system faults, even in the event of the smallest acoustic change. (6) Sound insulation on the inside StratocellWhisper-FR-400 mm

0 Comments

Leave a Reply. |

AuthorWe specialize in reducing noise emissions and increasing the performance of HVAC and industrial systems. Archives

January 2025

Categories |

We support you in solving noise problems - even at your premisesSilent Engineering

di Vicari Romolo Via Trento 22 IT-23875 OSNAGO (LC) www.forcotech.com [email protected] Phone: + 39 349 431 73 42 Contact Form VAT ID: 03833150133 Fiscal Code: VCRRML61E28Z133R Data Protection, Privacy, GDPR More Information ©Copyright (copyright notice) 2019/ 2020 / 2021 / 2022 / 2023 / 2024 - Silent Engineering - All contents of this website are subject to copyright. All content, in particular texts, images, logos, product names and graphics are protected by copyright. All rights, including reproduction, publication, editing and translation, require the express written authorisation of the website owner. This will only be granted after verification via PEC mail or registered letter. |

Our Brands around soundproofing |

RSS Feed

RSS Feed