|

Ejectors in heat pumps

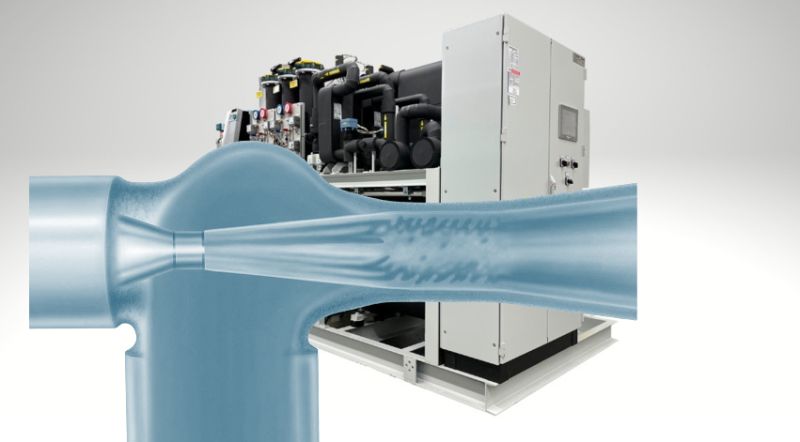

Ejectors are innovative components that are used in heat pumps to significantly increase their efficiency. They enable a significant increase in efficiency by optimising and partially recovering the compression work required in the compressor. How ejectors work Ejectors work according to the Venturi principle. A high-pressure flow is accelerated through a nozzle, which leads to a drop in pressure. This pressure drop creates a vacuum, which makes it possible to attract a low-pressure flow (suction flow) that mixes with the high-pressure flow. The kinetic energy in the diffuser is then converted back into pressure energy, which leads to an increase in the pressure of the total mass flow. Advantages By recovering throttling losses, part of the compression work can be saved, which increases the overall energy efficiency of the heat pump Ejectors can significantly reduce the required power of the compressor or even replace a compressor stage in multi-stage systems. Ejectors allow adaptation to different operating conditions and can be used in different configurations to optimise performance. Challenges Despite their advantages, ejectors are not yet widely used in practice. Ejectors need to be precisely matched to their operating conditions, which places high demands on the design. Furthermore, uncertainty about the cost-benefit ratio is one reason why many manufacturers do not implement this technology. Overall, ejectors offer promising opportunities for increasing efficiency in heat pump systems, but require further research and development in order to optimise their application in industry and make them economically attractive.

0 Comments

Leave a Reply. |

AuthorWe specialize in reducing noise emissions and increasing the performance of HVAC and industrial systems. Archives

October 2025

Categories |

We support you in solving noise problems - even at your premisesSilent Engineering

di Vicari Romolo Via Trento 22 IT-23875 OSNAGO (LC) www.forcotech.com [email protected] Phone: + 39 349 431 73 42 Contact Form VAT ID: 03833150133 Fiscal Code: VCRRML61E28Z133R Data Protection, Privacy, GDPR More Information ©Copyright (copyright notice) 2019/ 2020 / 2021 / 2022 / 2023 / 2024 / 2025 Silent Engineering - All contents of this website are subject to copyright. All content, in particular texts, images, logos, product names and graphics are protected by copyright. All rights, including reproduction, publication, editing and translation, require the express written authorisation of the website owner. This will only be granted after verification via PEC mail or registered letter. |

Our Brands around soundproofing |

RSS Feed

RSS Feed